Electrical Construction Activity

Safety Measures for GAS HAZARDS

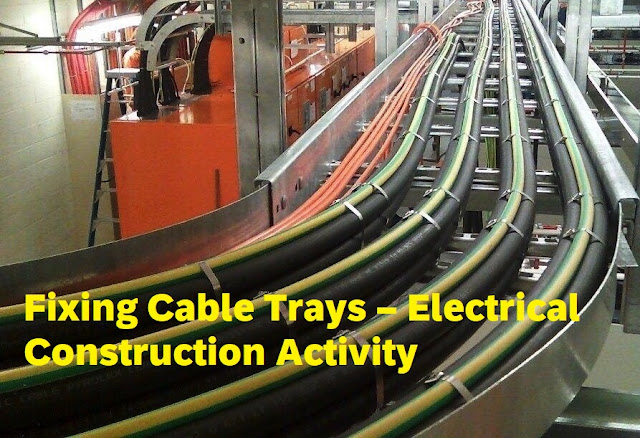

- Cable Trays & Ladders will be

“as specified” type as per the approved material & standard submittal.

- All accessories used such as

“bends”, intersections, risers, reducers, elbows, etc. “used in cable trays

& ladders will be of the same manufacturer as that of the trays &

ladders.

- Prior to start any installation

of Trays & Ladders, a complete coordination will be carried out with other

mechanical services to avoid any interference or interrupted for the service.

The hazards to be communicated with all the working team members.

- Tray / ladders routes will be marking at the ceiling before start any fixing of these items.

- Each run of cable trays &

ladders will be completed before installation of any cables. Each run will be

aligned, leveled & securely fastened to the ceiling / wall. Ensure ladders

are properly secured at bottom & top.

- Supports will be provided to

prevent stern on cables entering or leaving tray. Cable trays extending through

partitions & walls will be protected by fireproof noncombustible barriers.

- Sharp edges, burns &

projection will be removed for fixing the trays & ladders approved

suspension rods or steel angle brackets will be used at spacing not exceeding

1.5 meter and generally as shown on the approved drawings. Joints will be

positioned as close as practicable to the tray / ladder supports. Ensure the usage

of cut resistant gloves and all other PPE as required for this activity.

- The fitting of trays & ladders such as tees, bends & crossings will be connected with radial to permit cable-bending standards.

- Minimum clearance of 250mm will

be maintained between top of tray & ceiling.

- Cable arrangement will be in one

layer only, evenly spaced, with minimum spacing of two diameters of he larger

of the two adjacent cables, or of a trefoil formation of single core cable

circuit.

- Cable trays will provide direct

support to the cables without cleats or saddles wherever practicable purpose

made straps, cleats or saddles will however be used to maintain a neat or

regular disposition of cables. In vertical tray installation or where trays not

directly support the cables, load bearing cable cleats or saddles will be

employed and securely fixed to the tray. Manufacturer’s recommendations will be

followed in selection of cable cleats or saddles, on the basis of individual application.

Ensure the fall protection PPE and its anchored properly.

- Earthing jumpers will be

installed on trays & ladders between the lengths and where required to

ensure effective electrical continuity irrespective of whether a separate protective

earth conductor is required or not. Ensure there is no material stored below

the activity area.

No comments:

Post a Comment