CONTROL OF HAZARDOUS

ENERGY SOURCES

Its very important

to protect the employees against the inadvertent or unintended release of

energy, movement, or flow in electrical, mechanical, or material systems, which

could result in injury to employees. Energy isolation with Lockout of these

systems must be utilized.

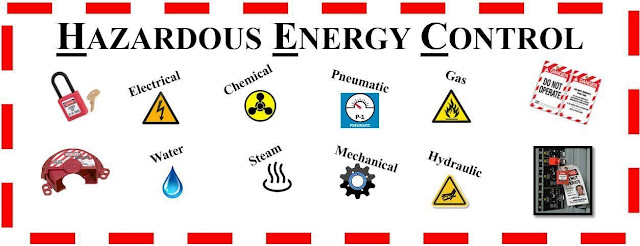

Hazardous energy control procedures will be used to ensure that machines or equipment being inspected are isolated from all potentially hazardous energy and locked out before employees perform any work activities where unexpected energizing, start up, or release of stored energy could cause injury to the employee and his coworker. All kind of energies to be considered in this program like electrical, mechanical, process, chemical, hydraulic, pneumatic, steam etc.

The Importance of Electrical Safety in Industry

The below listed

guidance for locking out(LOTO) machines and equipment. The equipment may, and

often will, include more than one energy source and/or multiple isolating points

for the safe maintenance. The energy sources will include electrical,

mechanical, hydraulic, pneumatic, and other forms of energy, such as residual

energy from spring tension or the effects of gravity. If at any time the

authorized employee is uncertain that the employer’s lockout procedures

sufficiently isolate and control all of the hazardous energy sources, the

authorized employee will not proceed with lockout, and will use alternate safe

procedures to document potential hazards. The written energy isolating procedure

with the training to all authorized and affected employee is very important in

hazardous energy control program for any industry.

1. Only an

authorized employee will lockout equipment. Every authorized employee exposed

to the hazard must lockout the equipment – LOTO(Lock out & Tag out)

2. Only locks and tags issued by the employee/agency that are designated for lockout purposes are permitted for use by authorized employees. Authorized employees are not permitted to borrow locks for use.

3. The authorized

employee will comply with OSHA requirements and with the employer’s lockout

program as long as it meets or exceeds the OSHA requirements.

4. The

authorized employee will assure that the employer’s authorized employee fully

de-energizes the equipment/machine and utilizes an appropriate and effective

energy isolating device(s) for the equipment/machine. The verification of

isolation is very important to know the equipment is fully isolated. The

authorized employee will then place his or her lock(s) on each isolating device

for the equipment along with any other person(s) that may be exposed.

Ensure Safe Handling of Gas Cylinders

5. After ensuring that no personnel are exposed to hazards, the employer’s authorized employee will conduct a verification of the lockout by operating the push button or other operating controls to assure that the equipment will not operate. The isolation verification to recorded. The authorized employee will observe the employer’s authorized employee return the operating controls to the off or neutral position after the test. At no time will the employee attempt to activate/operate the employer’s equipment. Many industry the personal LOTO system is followed.

6. Once the

equipment is locked-out, the authorized employee will limit their time of

exposure to the absolute minimum needed to complete the inspection.

Chemicals Hazards, Storage & Protection

7. The

lockout device will only be removed from the energy-isolating device by the

authorized employee who applied it. When the employee removes a lockout device,

the employee must notify their responsible Manager(s) prior to leaving the

worksite.

8. If the lockout device is unintentionally left on the equipment, the employee’s responsible Manager(s) will contact the employee to verify their location and the employee will return to the site for lock removal. Where the employee cannot return to the site, the employee’s responsible Manager(s) may authorize removal of the lock only after the employee’s location is verified and the employee is informed of the lock removal.

No comments:

Post a Comment